Last week was week 1 and I’m amazed at how much have been accomplished already. Guys sorry, there’s going to be photo overload today 🙂

So on day 1 (19 April, Monday), concrete block pallets were positioned and the cement mixer set up in the morning.

At the end of the day, the first floor outer walls were already erected.

If you notice in the photos, most of the houses in our neighborhood are built using hollowed fired bricks. Apart from one other house, we’re the only ones who used these concrete blocks. When we began this project, we also debated over this because most of the builders we talked seemed to favor the “red” blocks over the concrete blocks, which are more lightweight and porous. But after some research, I found that this difference in density doesn’t really figure in the thermal or sound conductivity of the walls, perhaps in their load bearing capacity but that really depends on the type of structure to be built. For another, one is not really cheaper than the other, so in the end we factored this out of the decisionmaking. What did require deeper rumination for us was the choice of wall structure, which I shall describe shortly 🙂

Moving on to day 2 (Tuesday), scaffolding was set up in the morning. Facing bricks were also delivered and interior walls in the first floor completed.

Also, wall core insulation (I think of the organic variety) was fixed on the concrete walls and brickwork started.

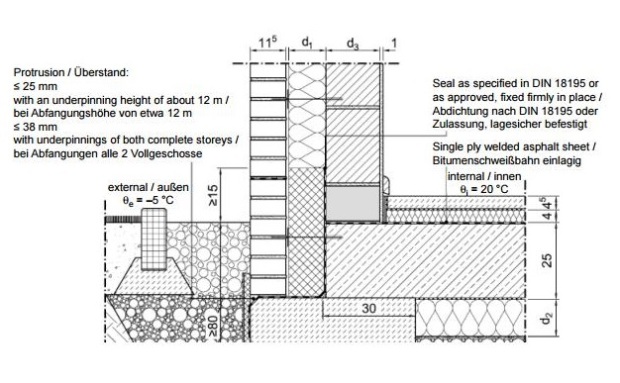

Regarding the wall structure, here‘s an illustration of the wall construction from the base plate. So the thickness of the outerwalls will come to about 40 cm, with 11.5 cm brick masonry, 12 cm core insulation (plus 1.5 cm gap), 15 cm concrete inner shell and about 3 cm wall finishing. The resulting U-Value (measuring thermal conductivity) is not really of the Passivhaus level (for which we’d need at least 24 cm thick innershell and at least 14 cm insulation), but in terms of cost-effectiveness, I think this made more sense for us. We also preferred this over the thermal composite wall system, which uses a synthetic polystyrol foam (much like styrofoam only denser and harder) as outer insulation because then it’d feel like the house is wrapped in a plastic bag. Think of internal humidity and moisture condensation, how is the house suppose to “breath”? Of course, it’s already standard for houses of this type to have some sort of ventilation system to prevent mildew/mold build-up. But I think we still liked the idea of a more “organic” house.

On day 3, bricking was continued to finish the first floor. First look at the bricking on day 2, I got worried that it’s not exactly how I saw it in the model house. It looked a bit severe to me and dull, not the nuanced effect with the original red fireclay showing through the burnt anthracite color. Anyway, I was worried for nothing. It got better as entire walls were completed.

Day 4 (Thursday) was the laying of concrete boards for the ceiling/second floor. So the slab guys were back to do this 🙂

These concrete boards are temporarily supported by beams held up by these red metal posts.

But basically these concrete slabs are anchored in these insulated metal beams (with pink sidings) that are fixed to the outerwalls. The weight in the middle will rest on the two main interior walls. Now I understand why it’s messy business installing recessed lighting in the first floor ceiling because then we’d have to drill through metal and concrete. They said this also might compromise the integrity of the structure, so when we brought this up during the design consultation, we’re told these would have to be reviewed first and factored in their “calculations”.

As with the baseplate, 2 layers of steel mesh were laid out on top and concrete was poured on day 5 (Friday), to be dried over the weekend.

D was disappointed he missed the pouring. But overall, we were impressed with the amount of work already done. The engineer told us that roof should be boarded up by Tuesday and hopefully already tiled by the end of the week. So far, it’s looking like they could really deliver in 3 months. But I’ll remain cautiously optimistic 😀